Building a Safer Shop

By Kyla Hunter

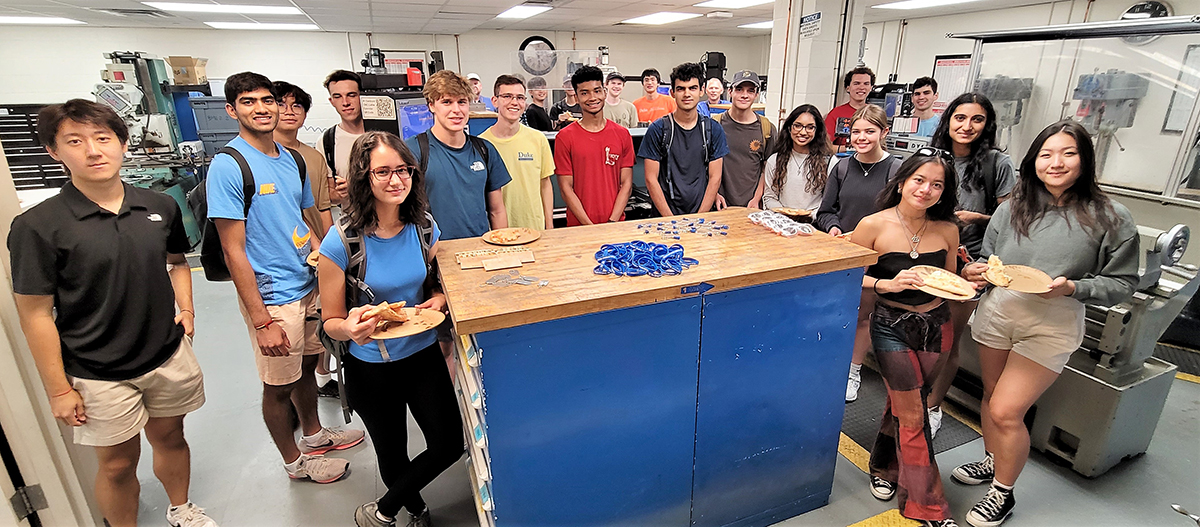

Pratt’s student shop staff teach that respect for the shop environment is paramount

When engineering student Katie Drinkwater signed up for the Machine Shop Tools Mastery Unit for her Engineering 101 class, she was completely unsure about what to expect. The Tools Mastery Units are a part of the curriculum designed to introduce students to various skills and resources on campus. The units range from woodworking, to 3D printing, to the one Drinkwater picked: the machine shop.

Tucked away in the former telecom building on the engineering side of campus, the student shop is a valuable resource that remains a mystery to many members of the Duke community. As a freshman with no prior experience, Drinkwater felt especially intimidated by the prospect of stepping foot into a place with such powerful and potentially dangerous machinery. Four years later, as a senior in Pratt and a member of Duke Motorsports, she has since become much more comfortable using power equipment like lathes and bandsaws. Along with many other members of the Duke community, she attributes much of her positive experience to the guidance and support of Duke Machine Shop Manager, Steve Earp.

“When I went in to make my first part, I was very nervous and intimidated,” Drinkwater says. “I thought that I would be expected to know how to use the machines, but this couldn’t have been farther from the truth. Steve helped my partner and me with every step but didn’t infringe on our ownership of the project. I always feel free to ask questions and check in with Steve, but I am still expected to do my own work.”

Earp has managed the student shop for nearly 15 years and is a vital and beloved mentor to the students who frequent the shop. Not only is he responsible for the set-up, organization, and operation of the shop, but Earp also ensures that thorough safety practices are properly established and upheld. Part of this dedication to safety involved spearheading a brand new initiative: the Student Shop Managers Consortium.

In 2011, following an accident at Yale University that involved the death of a student using the student machine shop, Earp became determined to take action to prevent future tragedies. “I started investigating, trying to find other people that do my job at other universities,” he explained. After sending out an email to dozens of other engineering schools, Earp was left with no responses. However, he refused to let this deter him. “I had to drill down over the next two years and find that one guy or gal that operates and manages that shop,” he recalls. One by one, Earp built a network across the country, eventually organizing and hosting the first conference here at Duke University in 2015 with about 65 student shop managers. Earp recalls the positive feedback from the attendees; for many of them, it had been their first opportunity to connect with those in similar positions. “Nobody ever knew that there was somebody like them somewhere else,” said Earp.

“I thought that I would be expected to know how to use the machines, but this couldn’t have been farther from the truth.”

Katie Drinkwater

Since then, the conference has occurred annually, and is hosted by different universities, including Yale. It was even held virtually during the pandemic. Most importantly, this network has allowed for more conversation and accountability in making student safety a priority. Because of his passion for student shops and commitment to student safety, Earp was recently named the president of the Student Shop Managers Consortium.

In addition to Earp, there are two other full-time faculty members in the student shop. Greg Bumpass, the assistant manager, has been there for over 10 years. As the primary person in charge of running safety training, he is well known for his ability to create a welcoming and approachable environment. His favorite advice to calm nerves is to remind students that everyone starts somewhere. “If I can do it, you can do it,” is his motto. Daniel Creager, who joined the shop staff in Fall 2022, is the senior instrument maker and has experience as a professional welder.

The emphasis on safety is something Katie has experienced since the first time she stepped in the shop to complete her Tools Mastery assignment. “A machine shop can be a very dangerous environment, so he and Greg take safety training very seriously,” she explains. “They want every student to respect the environment instead of being afraid of it.” After completing the very thorough online and in-person components of the safety training, Drinkwater felt proud to pick up her shop badge.

“They want every student to respect the environment without being afraid of it.”

katie drinkwater

Given the countless classes, research labs, and student groups that make use of the machine shop, Katie is in good company. Duke AERO is a student group that works on designing and building high-powered, solid-fuel rockets. Duke Electric Vehicles is a student-run organization with a mission to enable more sustainable transport by inventing future electric vehicle technologies. The team currently holds two Guinness World Records for vehicle efficiency. Duke Motorsports, also known as Formula SAE, consists of students that design and build an open-wheel, formula-style race car. Each year they start from the ground up, and work towards the goal of bringing their finished car to competition at the Michigan International Speedway. Duke Robotics competes every year in a Navy-sponsored competition for fully autonomous underwater submarines and has placed in the semifinals or higher every year since 2001. All of these organizations make frequent use of the machine shop to create and modify parts that are critical to their goals. John Smalley, the president of Duke AERO, cites Earp’s help in working on projects, making custom tools, and “solving problems that seemed impossible.”

Ultimately, it is not the machines, but the people who run them, that make the machine shop such a valuable resource. The combination of technical expertise and an encouraging attitude creates an atmosphere conducive to growth and productivity. Earp and Bumpass, who have both completed a rigorous four-year apprentice program managed by the state of North Carolina to earn the designation of Journeyman Tool and Die Maker, embrace their roles not just as highly educated and skilled professionals, but as teachers and mentors. Students from all grades and majors who have stepped into the shop, even on a single occasion, will enter having recognized a friendly face, and leave having learned something new. In a sentiment echoed by the engineering community, Drinkwater concludes, “I feel very lucky to have Steve as our shop manager. His wealth of experience, genuine interest in students’ learning, and good-humored disposition are extremely valuable additions to the Pratt community.”