Leaves’ Pores Explain Longstanding Mystery of Uneven Tree Growth in a Carbon-Enriched World

The mechanics of how water and carbon dioxide move in and out of plants greatly affects how trees grow in a carbon-dioxide-enriched environments.

A new grant awarded to a Duke-Cambridge team attacks the challenges of creating digital twins of geometrically complex systems

Over the past couple of decades, computers have become more powerful, simulation techniques have become more sophisticated, and sensors have become smaller and more accurate. This combination has given rise to a concept called a “digital twin,” where complex machines and systems are represented virtually in real-time with real-world input and adjustments.

If executed well, digital twins represent an enormous opportunity to increase a machine’s efficiency and productivity. Given accurate enough simulations, they should be able to predict useful tweaks to operating conditions and which parts of the whole are most likely to break down and when.

While these types of performance boosters have already been demonstrated for relatively simple machines, real systems with miniature details and complex geometries still pose a problem. But it’s a problem that Duke engineers, in collaboration with colleagues from the University of Cambridge, are looking to solve with the support a new $815,000 grant from the National Science Foundation and the UK Research and Innovation.

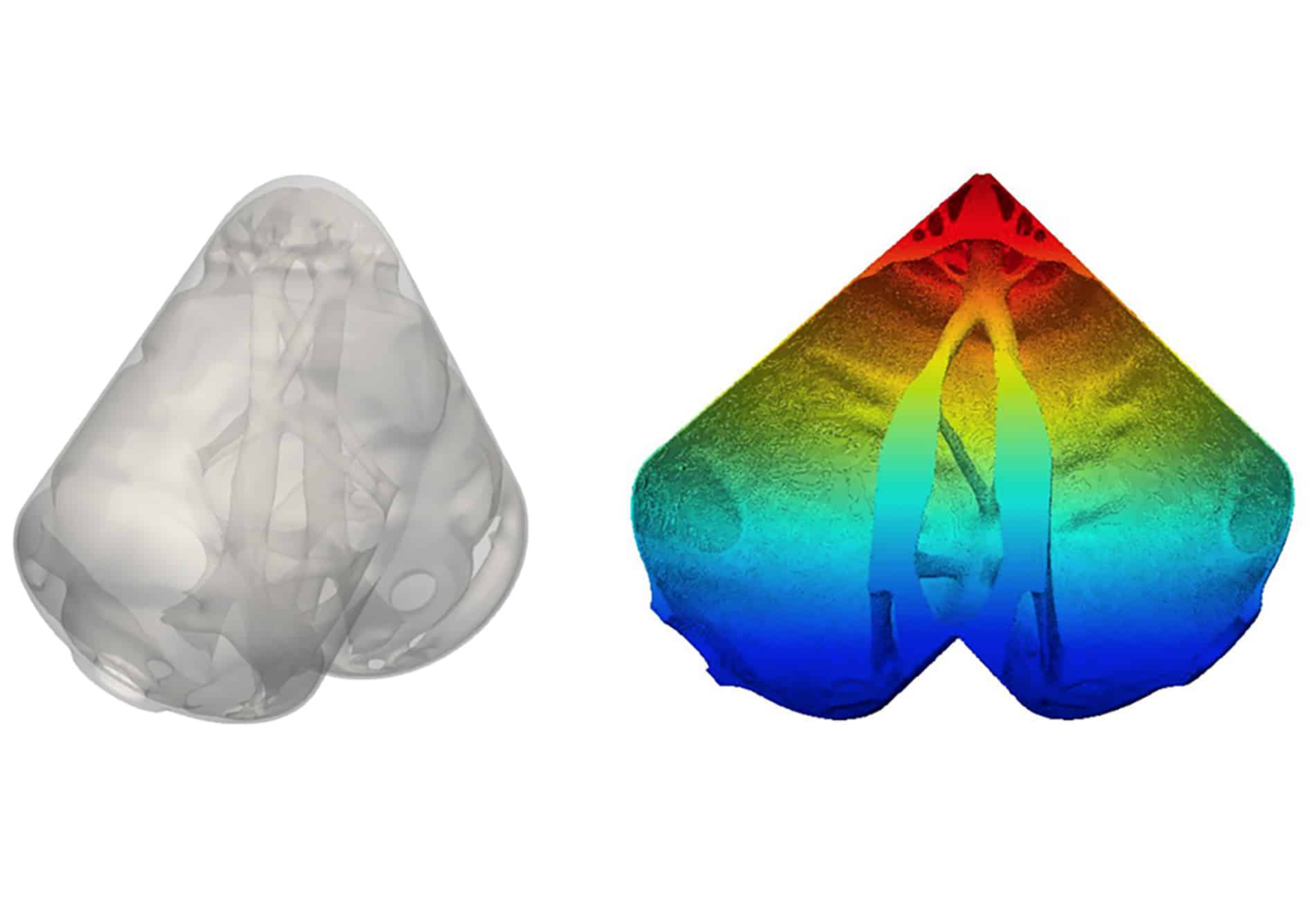

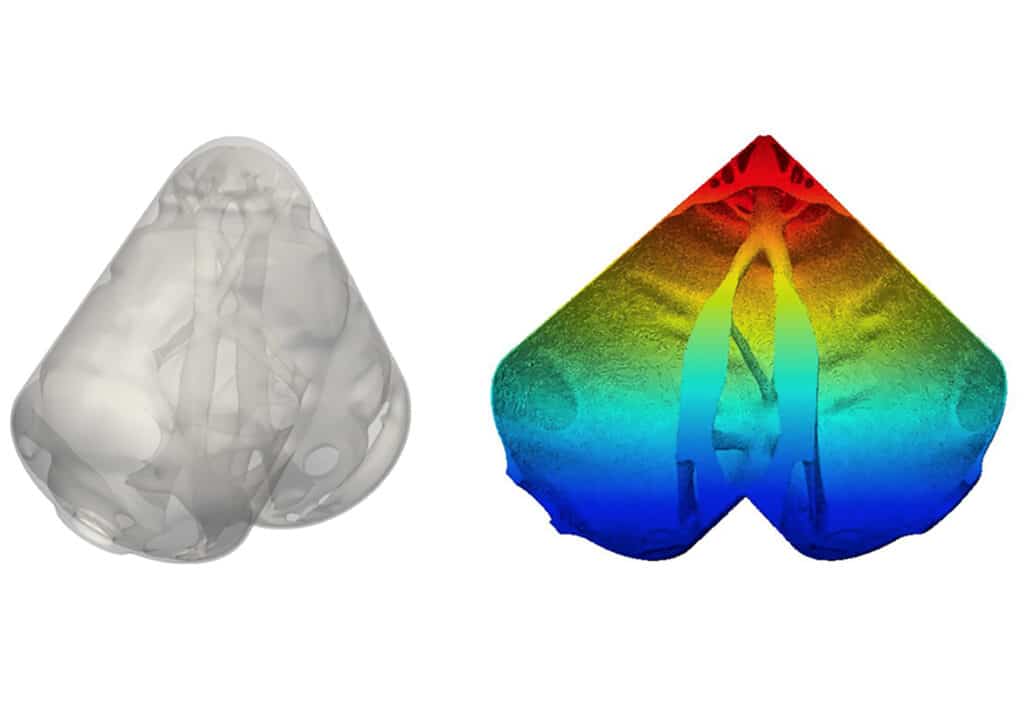

The challenge with complex geometries comes from the way in which typical modeling algorithms handle them. In most cases, software will break down a component of a machine into smaller pieces, creating a subdivision of volumes into (computational) cells, which look like a puzzle or a three-dimensional distorted checkerboard. As details become more minute and geometries become more complex, these programs called computational grid generators may break down. Additional problems arise, since the computer graphics algorithms used for shape representation may not produce watertight volumes. These issues make the overall simulation process too long and break down its automation, which is essential to efficiently create digital twins at scale.

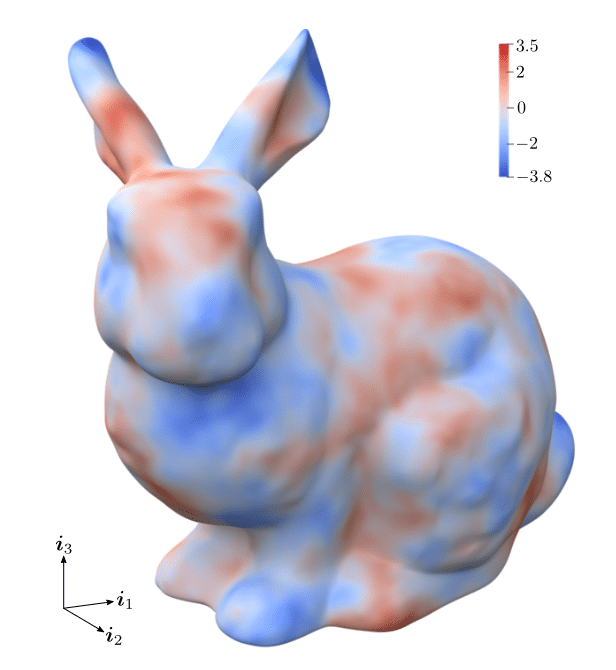

Guglielmo Scovazzi, professor of civil and environmental engineering at Duke, is looking to apply a workaround solution his lab recently invented to the challenge. Called the Shifted Boundary Method (SBM), the approach essentially creates a standardized 3D lattice of computational cells upfront and immerses any geometric shape to be simulated into it. Then all computational cells that are cut by the shape are removed from the simulation.

“A complex geometric shape is represented in an approximate way, as in the popular LEGO toys,” Guglielmo said. “But we have a special algorithm to correct the roughness of the surfaces to maintain the required accuracy. This simplifies tremendously the simulation task, which is now fully automated.”

This approach will be combined with another called Probabilistic Subdivision Surfaces to create an even more faithful, lifelike digital twin. Created by Fehmi Cirak, professor of computational mechanics at the University of Cambridge, this technique introduces random perturbations and noise into the geometry of the model. This strategy recreates the uncertainties/tolerances due to the manufacturing of machine’s components and the real-world wear and tear caused by their use over time.

Together, the duo aims to build a computational methodology that anybody can use to implement more accurate digital twins of any system they are interested in, no matter how complex. The approach, the researchers hope, has the potential to revolutionize the large-scale deployment of digital twins in industry and applied fields.

The mechanics of how water and carbon dioxide move in and out of plants greatly affects how trees grow in a carbon-dioxide-enriched environments.

The Duke Climate Collaboration Symposium explored the history of geothermal energy at Duke and accelerate its use along the East Coast.

Stumped by high levels of PFAS contamination in Chapel Hill and Pittsboro drinking water, Lee Ferguson used new methods to find the source of the pollution upstream.