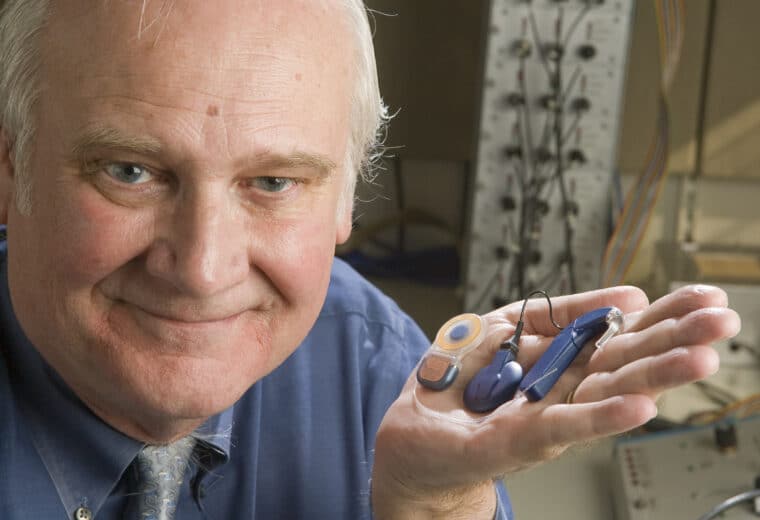

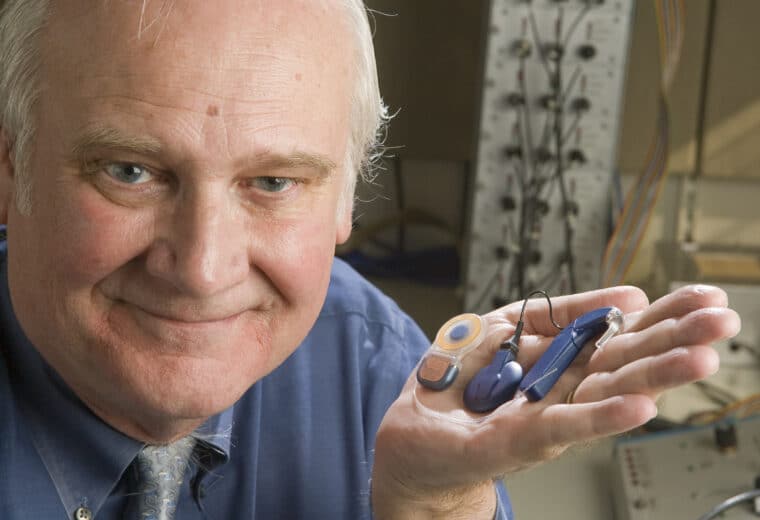

Blake Wilson Awarded 2026 Queen Elizabeth Prize for Engineering

Wilson shares this prize for his contributions to the development of the cochlear implant.

We’re sorry—the news story you were looking for has been archived.

Please see the most recent stories below.

Wilson shares this prize for his contributions to the development of the cochlear implant.

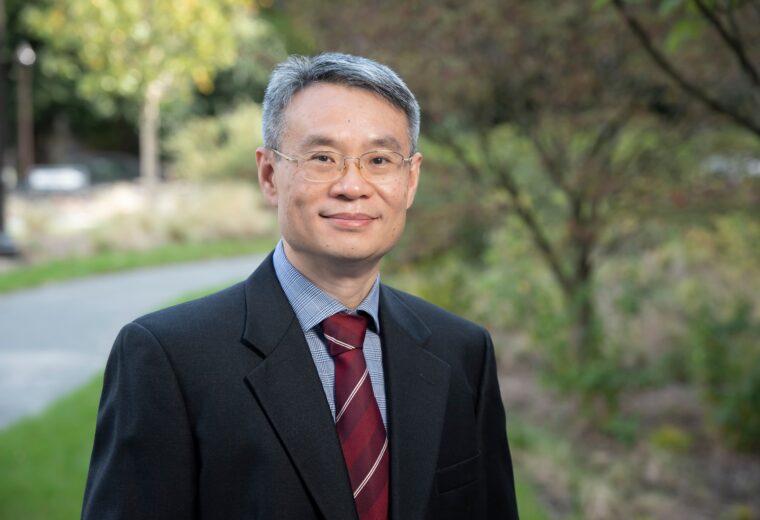

Yiran Chen develops brain-inspired semiconductor hardware to enable faster, greener AI at the edge.

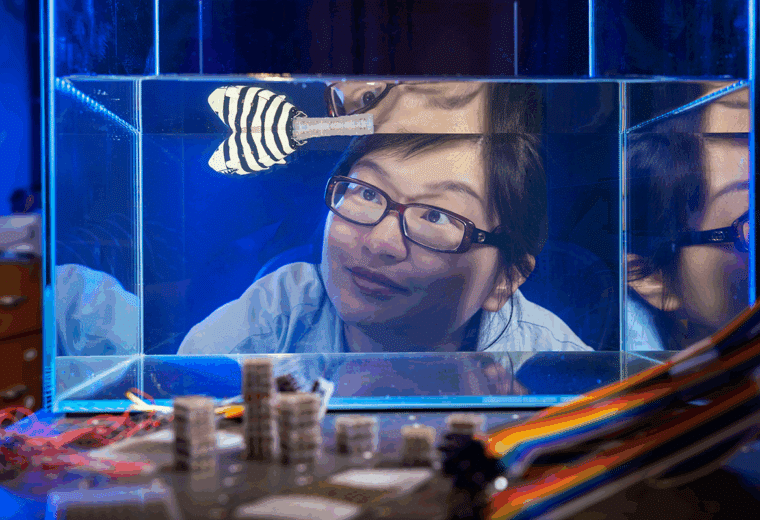

Electrically heated elements turn from solids to liquids to provide flexibility to robotic building blocks.