The Student Experience at Duke: From Tool Shop Neophytes to Madcap Creators

Miranda Volborth

Duke’s makerspaces transform students into confident builders, no matter where they start

Duke engineering students arrive at their first day of classes equipped with a dazzling array of skills and talents. Whether they’re elite athletes, polyglots, musicians or budding entrepreneurs, they’ve all demonstrated ambition and academic excellence.

Duke engineering students arrive at their first day of classes equipped with a dazzling array of skills and talents. Whether they’re elite athletes, polyglots, musicians or budding entrepreneurs, they’ve all demonstrated ambition and academic excellence.

But some of these aspiring engineers have never even picked up a hammer or used a power drill, let alone tried their hand at 3D printing.

“No worries,” said Ali Stocks, who manages The Foundry, a 7600-square-foot maker space in Gross Hall on West Campus. The Foundry’s staff, Stocks said, can teach any student how to use just about any tool in the space: laser cutters, drill presses, bandsaws, milling machines—and yes, even hammers.

“Hello, World.”

The Foundry occupies a swath of the recently renovated Gross Hall alongside the Duke Energy Initiative, iiD and numerous research labs that sit nearly within shouting distance of Harrington Engineering Quad. The main “pit” of the Foundry is set up for classroom instruction and project-based learning; though the Design POD is the flagship space for First-Year Design, several sections meet here, under Stocks’ mentorship.

First-Year Design is an engineering student’s earliest taste of their potential future profession. In this introductory class, students work in teams to solve problems put to them by real-world clients in the university and surrounding community. The goal of each team is to deliver a prototype solution to their client by the end of term.

Stocks mentors some of the First-Year Design teams and knows that successful projects start with a team of confident builders—which is why the Foundry staff makes tool training as easy as possible. Students can sign up for individual training by scanning a QR code and filling out a simple form with the options they’re interested in. Workshops are held regularly, too, in woodworking, soldering and laser cutting.

“Once they get their feet wet and realize they can make things, they’re off and running.”

ALI STOCKS | MANAGER of THE FOUNDRY

Once they get their feet wet and realize they can make things, they’re off and running,” said Stocks, indicating a bank of 3D printers on one wall. “There’s no telling what I might find here on Monday morning. There are figurines, gears, parts… stuff they had no idea how to make at the beginning of the semester.”

Across West Campus, the staff at the Innovation Co-Lab are busy with their own student onboarding.

The Co-Lab functions a lot differently today than it did in its early days, when it mostly existed for academic computing support. While it still offers original training for people who are interested in web development, in the form of its Roots program, other tools have been added according to demand. Among its many resources are 3D printers, laser cutters, water jet cutters, CNC machines, and even satellite locations at the Rubinstein Arts Center and in Lilly Library.

The Co-Lab functions a lot differently today than it did in its early days, when it mostly existed for academic computing support. While it still offers original training for people who are interested in web development, in the form of its Roots program, other tools have been added according to demand. Among its many resources are 3D printers, laser cutters, water jet cutters, CNC machines, and even satellite locations at the Rubinstein Arts Center and in Lilly Library.

It looks a lot different, too.

“For new users, it might be overwhelming to step into the space,” said Michael Faber, who manages the Innovation Co-Lab program. “That’s why we make sure the barriers to entry are super low.” The Co-Lab recently launched First Fridays, where students are invited to make stickers on a Cricut machine, a home printer-sized electronic device that precisely cuts shapes from materials like vinyl and card stock. Students bring a favorite digital image or pick something out when they get to the Co-Lab. In just a few minutes, they’ve learned how to use the Cricut, and they walk out with something they made themselves.

“For new users, it might be overwhelming to step into the space,” said Michael Faber, who manages the Innovation Co-Lab program. “That’s why we make sure the barriers to entry are super low.” The Co-Lab recently launched First Fridays, where students are invited to make stickers on a Cricut machine, a home printer-sized electronic device that precisely cuts shapes from materials like vinyl and card stock. Students bring a favorite digital image or pick something out when they get to the Co-Lab. In just a few minutes, they’ve learned how to use the Cricut, and they walk out with something they made themselves.

“It’s a ‘Hello, world’ experience,” said Faber. “The hope is that the same student might then sign up for our newsletter to hear about other events, or take a Roots workshop, or maybe come in and try to make something on a 3D printer, even if it’s just a Pokemon figurine.”

On the back side of the same building, there’s yet another resource for engineering students: the Pratt Student Shop. There are no Pokemons to be found here— the space is reserved exclusively for course work. But the space is well equipped with lathes and bandsaws, laser machines and plasma cutters, and tool-savvy staff supervise students as they work. The shop is available to engineering students who pass a two-part safety test.

The Wonder Years

As engineering students move out of their first year and on to more elaborate design and production tasks, they use the university’s makerspaces in new ways and operate with more independence.

[video:youtu.be/5ghDJWE0tis]Electrical and computer engineering professor Martin Brooke’s Ocean Engineering class operates out of the Foundry, where they have easy access to the tools and equipment they need to build drones designed to sample rain forest biodiversity. Bass Connections and Global Health teams also use the space; cupboards lining the walls are scrawled with the names of the teams that work there and are filled with in-progress projects like portable laparoscopes—small, flexible cameras used in surgery.

Upstairs, student groups and clubs have been assigned rooms accessible 24 hours a day via key card for those who have completed the requisite safety training. Duke Electric Vehicles, Duke AERO, the Academy of Model Aeronautics, Duke Conservation Tech and Duke Robotics Club all make their homes in the space.

When conferences and competitions draw near, the student groups are doubly glad to have a dedicated place to work. In the weeks leading up to the annual RoboSub competition, for example, up to 30 members of the Duke Robotics Club can be found in the Foundry on Thursday nights and Saturdays testing the systems on their autonomous submarine.

[video:youtu.be/CTE6zJp0C8M]“Having our own space in the Foundry is extremely useful. It gives us a single place to keep all our supplies and raw materials while storing sensitive electronic equipment properly. We also have our own areas to solder, anodize and carry out other tasks that would be dangerous to perform outside the Foundry’s lab setting,” said Duke Robotics Club President Nick Chakraborty ECE’23.

Anuj Thakkar, who graduated from Duke Engineering in 2020 with a degree in mechanical engineering, was similarly fond of the Co-Lab.

“I came into Duke with no hands-on experience,” he said. “I didn’t know how things were built or assembled. I filled out paperwork to drop Pratt before I even started classes.”

“I came into Duke with no hands-on experience. I didn’t know how things were built or assembled. I filled out paperwork to drop Pratt before I even started classes.”

Anuj Thakkar’20 | Mechanical Engineer

But as fate would have it, Thakkar wandered into the Co-Lab before he made his decision. “The staff there made me feel that inexperience was ok—that it was ok to learn and to mess up, that a broken machine was no big deal, and that it was just a part of learning and trying things.”

Thakkar began to spend a lot of time in the Co-Lab, soaking up everything he could from the experienced fabricators staffing the lab. “They’re not pushy, but they’re always there to offer great advice if you need them,” he said. “Of course I learned through the engineering curriculum how to design things, but the Co-Lab allowed me to bring that theoretical knowledge into a hands-on environment and figure out how to actually build those products.”

And make things he did. “I made the stupidest, craziest things I could think of,” Thakkar said happily. There was a chocolate drone, a levitating speaker and a semi-flexible, washable brace to protect his own broken wrist. Then he made a monowheel that was funded, in part, by a grant from the Co-Lab.

[video:youtu.be/OPLzuDfOGAk]Those grants exist to feed interest and excitement. Notably, proposals do not need to be tied to any specific academic outcome.

“The whole point is to be here and be inspired,” said Faber.

Maker Spaces Make Impact

While the Co-Lab aims to foster creativity just for the sake of creativity, it also houses plenty of projects with measurable real-world impact. In the spring of 2020, several projects quickly launched in support of healthcare workers facing what was at the time an unfamiliar new threat to human health: COVID-19.

“The world was a whirlwind,” said Konstantinos Economopoulos MD, PhD, MEng who is a fifth-year surgical resident at Duke. As the university locked down, he recalled, the Co-Lab was one of the few spaces that remained open to people actively working on strategies to combat viral transmission.

“We had to really think outside the box about how to attack the problem of having a very low supply of personal protective equipment.”

Konstantinos Economopoulos MD, PhD, MEng | Surgical Resident

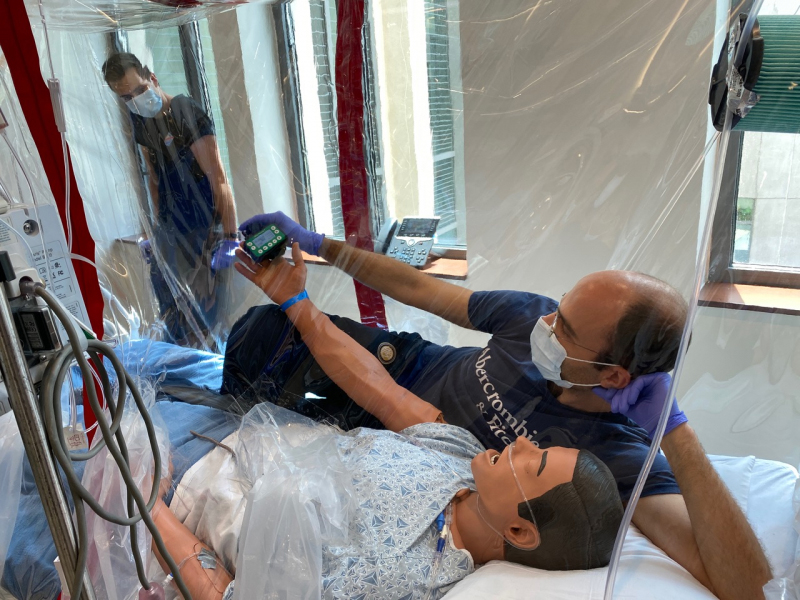

Economopoulos, who was a Design Health fellow and a Master of Biomedical Engineering student at the time, was one of those people. “We had to really think outside the box about how to attack the problem of having a very low supply of personal protective equipment,” he said. When research indicated that the virus was being transmitted to patients in part by the donning and doffing of PPE, his team decided to try moving protective measures closer to the patient. In the Co-Lab, they began prototyping a “bubble” that enclosed a patient’s bed and filtered the air inside. Drawing on their contacts and knowledge of supply chains, the staff were able to procure the necessary materials, which were in short supply.

The pace of the iteration cycle was breakneck; their product was revamped six times over two weeks before moving to a simulation lab at the School of Nursing, where they could quickly collect practical feedback from actual practitioners.

When the team proposed its product, COVIAGE, to Duke University Hospital a short time later, administrators saw promise beyond the current healthcare crisis and recommended that the team pursue FDA Emergency Use Authorization approval for their invention. That approval was granted in September 2020.

“The most amazing part of the experience was how everyone involved was so engaged and willing to help. The level of interdepartmental collaboration was incredible,” said Economopoulos.

In 2020, Newsweek and Make: magazine teamed up to create a list of the “Best Maker Schools in Higher Education.” To be considered for the list, a school must implement curricula that encourages learning through doing, emphasize collaborative problem-solving, offer physical makerspaces, and foster a diverse and active community of makers and doers.

To the surprise of no one who has taken a Duke Engineering course in the last decade, Duke University made the non-ranked list. And whether a student is launching a biomedical device company or simply learning how to hammer a nail, Duke has all the resources and support they need to get started.